Thesis Details

Basic information

Identification of whirl oil in induction motors using orbital pattern analysis

Ms.C. in Computer Engineering

Finished

Detailed infomation

Abstract

Failure Analysis in induction motors is a common industry practice that quickly grows when machinery is a main factor in extensive working hours. Induction motors are compounded by different electrical and mechanical components that are exposed to some wearing with prolonged use. This work has focused on detecting mechanical faults in electric induction motors, due to they are the engine most used in the industry worldwide. Historically, some works have focused on detecting some faults (most of them commonly identified) problems, avoiding future damage, while the maintenance is provided early. Induction motors can be classified by their size, power, number of phases, etc. However, misalignment, imbalance and the swirl of oil failures are common mechanical faults in all types of engines; these failures generate different external vibration levels.

Failure Analysis in induction motors is a common industry practice that quickly grows when machinery is a main factor in extensive working hours. Induction motors are compounded by different electrical and mechanical components that are exposed to some wearing with prolonged use. This work has focused on detecting mechanical faults in electric induction motors, due to they are the engine most used in the industry worldwide. Historically, some works have focused on detecting some faults (most of them commonly identified) problems, avoiding future damage, while the maintenance is provided early. Induction motors can be classified by their size, power, number of phases, etc. However, misalignment, imbalance and the swirl of oil failures are common mechanical faults in all types of engines; these failures generate different external vibration levels.

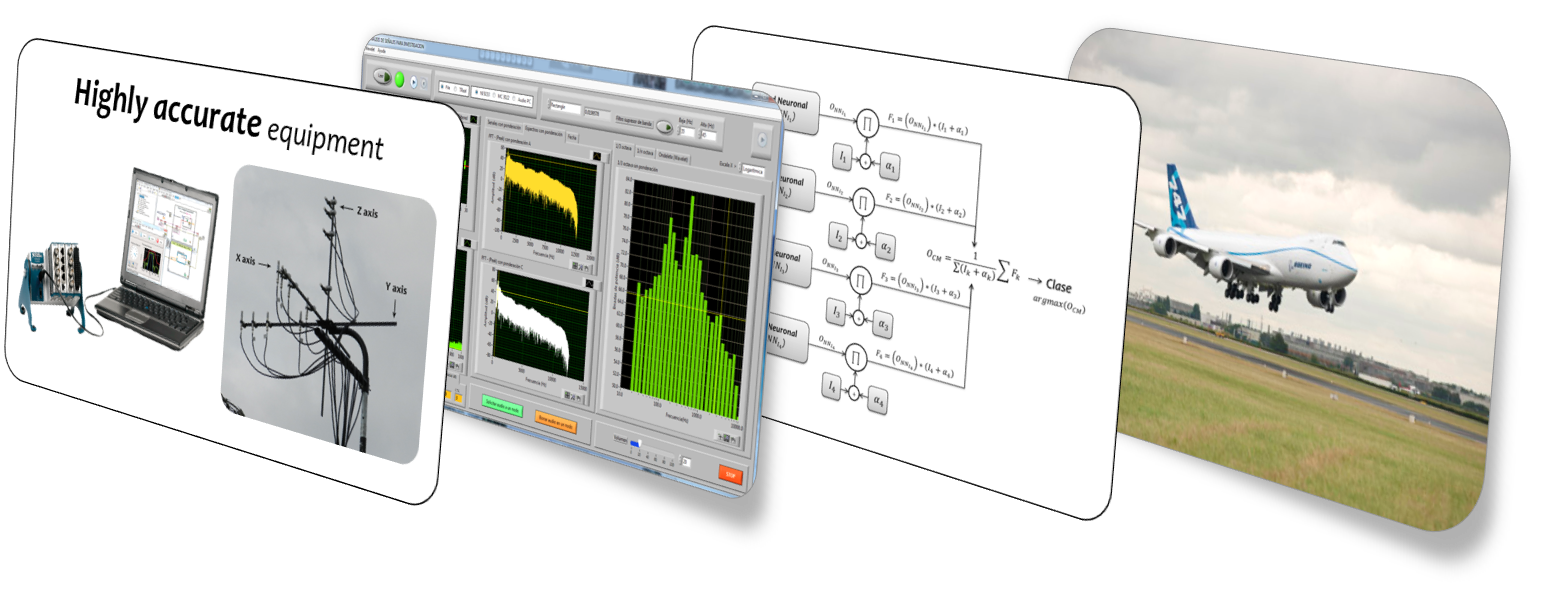

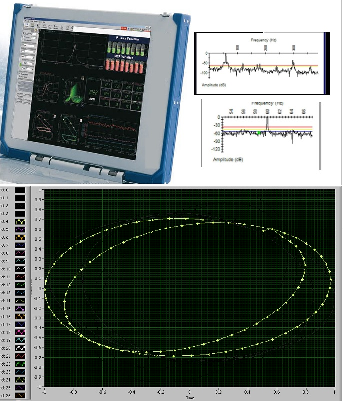

Several techniques can be used in the engine faults analysis, such as support vector machines, Fourier spectrum, wavelet filtering, and others. However, the complexity of a mathematical representation for the signal modelling in an engine and its application in real systems can be a difficult task. Therefore, a new technique using orbital analysis, which provides a convenient and easy way to recognize misalignment, balancing and swirl oil induction motors using neural networks has been proposed.

Orbit Analysis in engine failures has been used to model the normal operation of motors and it represent the basis of this research. In this case, three different motor faults at different vibration levels present a characteristic orbit with particular features, which can be used to determine when an engine presents a fault, before serious damage appears on the motor.

The research methodology has been divided into two parts: in the first step (data acquisition), vibration signals of induction motors are acquired using the data acquisition card NI USB-9233. Then these signals are used in the second stage (Analysis and Issue of diagnosis), where a mathematical analysis of the digital signal is processed through an designed algorithm for fault identification using a Feedforward Artificial Neural Network .

Authors

Directors

Highlights and contact

Newsletter Signup

Find out all group news and updates by subscribing to our website.